We practice Digitization, Digitalization, Digital Transformation

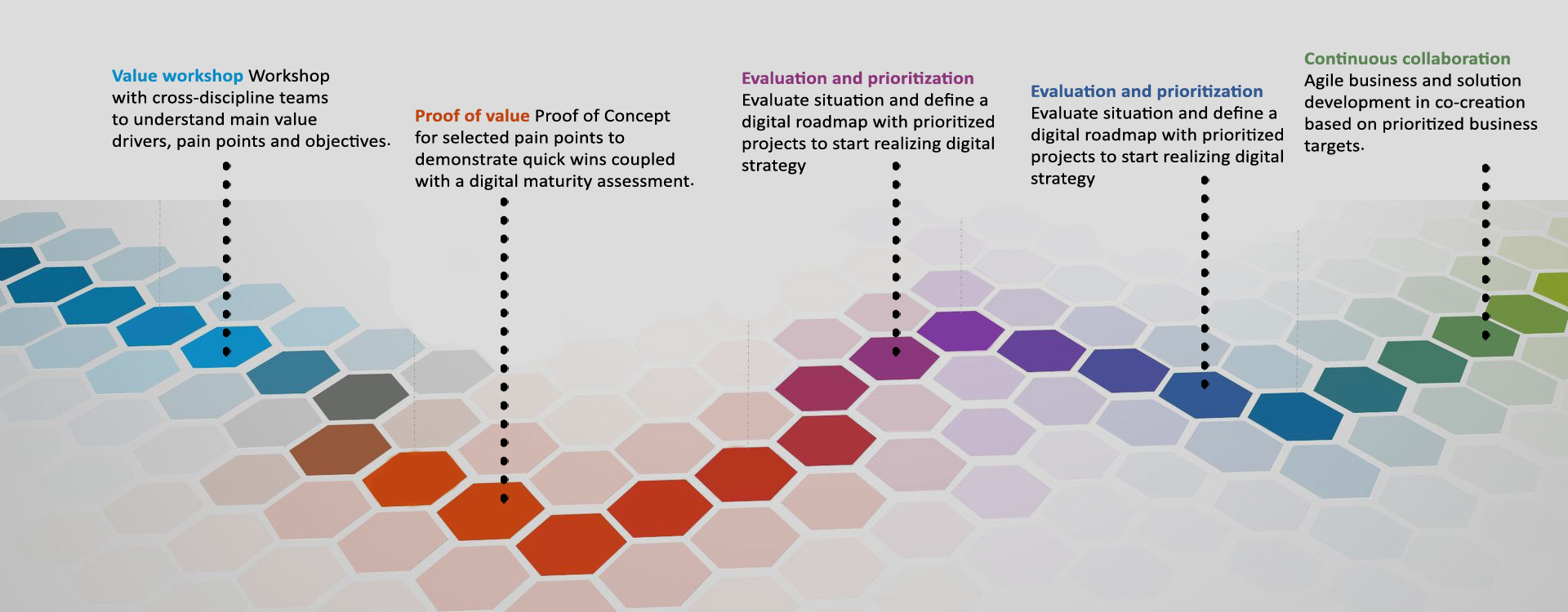

Industry 4.0 is a holistic automation, business information, and manufacturing execution architecture to improve industry with the integration of all aspects of production and commerce across company boundaries for greater efficiency. Technology development and digitalization create enormous opportunities for your company to increase customer value by streamlining processes, increasing quality, creating new revenue streams, and reducing production costs. But the challenges are significant. Digitalization of business requires a systematical approach, changes in leadership style, and a completely new mind-set in the production chain. The training program “Digitalization and Industry 4.0” is structured as a step-by-step-process in order to support companies of all sizes in their development.

Industry 4.0 Digitization systems capture a wide range of data that can be used to improve performance and productivity with the application of analytics. Analytics are used in a number of ways, including real-time predictive maintenance, which helps manufacturing companies avoid interruption of production by unplanned machine failures on the factory floor—directly improving asset utilization. Another application is optimization of production operations, improving productivity and energy efficiency

More generally, the possible evolutions of Business Models in the logic of "Digitalization 4.0" can be identified through the combination of different perspectives and dimensions: Value Proposition (products/services offered), Operating Model, Technology. Each of these perspectives can be seen in evolutionary sequence through the following incremental steps: Enhancement, Extension, and Re-definition. Let's examine some incremental reference configurations of the Business Model, synthesizing in a corresponding way the three dimensions "Products and Services", "Operating Model", "Technology"

Connected Consumers, Customized Experiences

As far as the Company's Operating Model is concerned, it must be analysed, and probably reviewed in an integrated way, in all its dimensions: Structure, Business Processes, Organisation, Management, Culture, Systems and Technologies. The following strategic capabilities can thus be enabled:

Levels to Achieve Digital Transformation

Use Cases for Digital Transformation Across Industrial Value Chain

Products and Services