SD Building, First Floor, 233, New Scheme Road

P.N Palayam, Coimbatore - 641037.

+91 422 4348717, +91 77087 34396.

info@digitalindustry.in

P.N Palayam, Coimbatore - 641037.

+91 422 4348717, +91 77087 34396.

info@digitalindustry.in

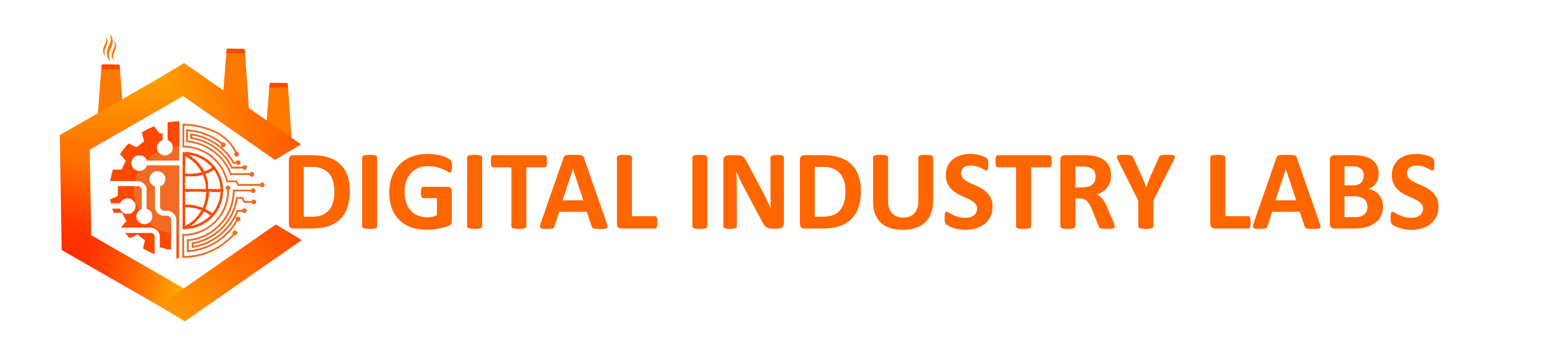

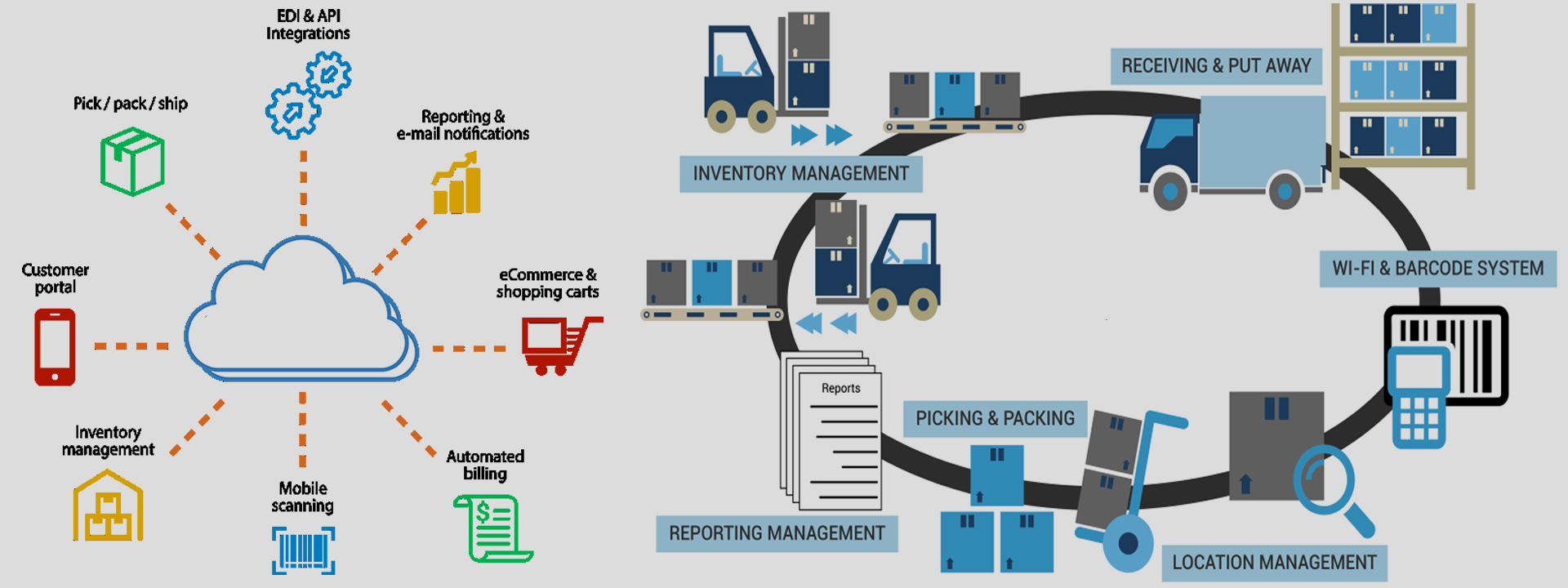

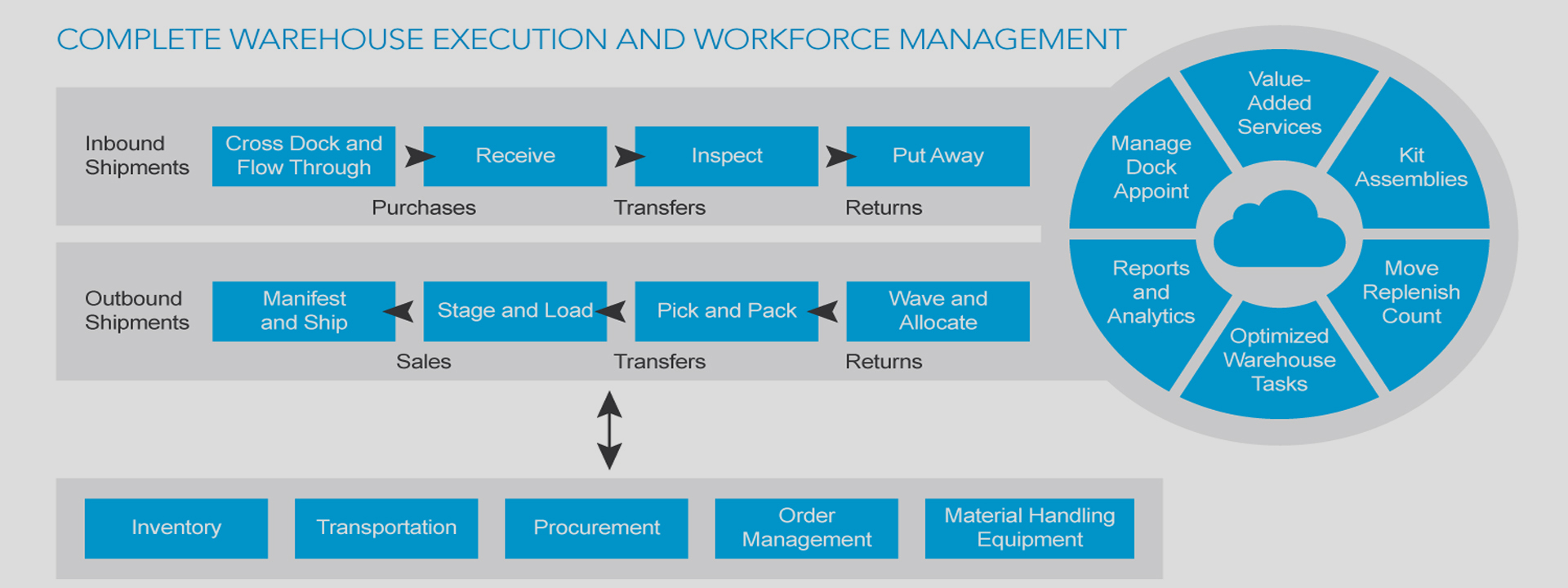

The Supply Chain Management solutions deliver intelligent, real-time supply chain orchestration by connecting companies to their supply chain partners and digitally transforming processes from planning to delivery both within and outside the enterprise. The warehouse management platform is available in the cloud and compliments operations of all sizes. It’s included features provide users with numerous ways to organize, optimize, and streamline their warehousing space and tasks. This system helps boost labour productivity while reducing inventory costs and improving the accuracy of daily warehouse tasks. This system includes a flexible environment that is easily configurable for a quick implementation process. Complex fulfilment support gives users the tools to handle moving large volumes of a product while staying accurate. The WMS enables companies to maximize their labour and space utilization and equipment investments by coordinating and optimizing resource usage and material flows. Specifically designed to support the needs of distribution, manufacturing, asset-intensive, and service businesses, Oracle Warehouse Management provides a single-platform across an entire global supply chain.

By connecting systems, trading partners, and devices, while digitalizing supply chain processes end to end, companies gain real time visibility and empower data-driven decisions that allow them to optimally deliver to their customers on time.

ALWAYS ON! ALWAYS CONNECTED!

Better Decisions in Complex Environments

AR Based Indoor Warehouse Management System

Benefits and Insights

Our WMS takes many time-consuming processes and automates them. This way, you can focus on problems that require a specialized human touch.

Our WMS Inventory is very responsive when it comes to support and troubleshooting. With this tool, you can move past problems and technical issues quickly and get things moving faster.

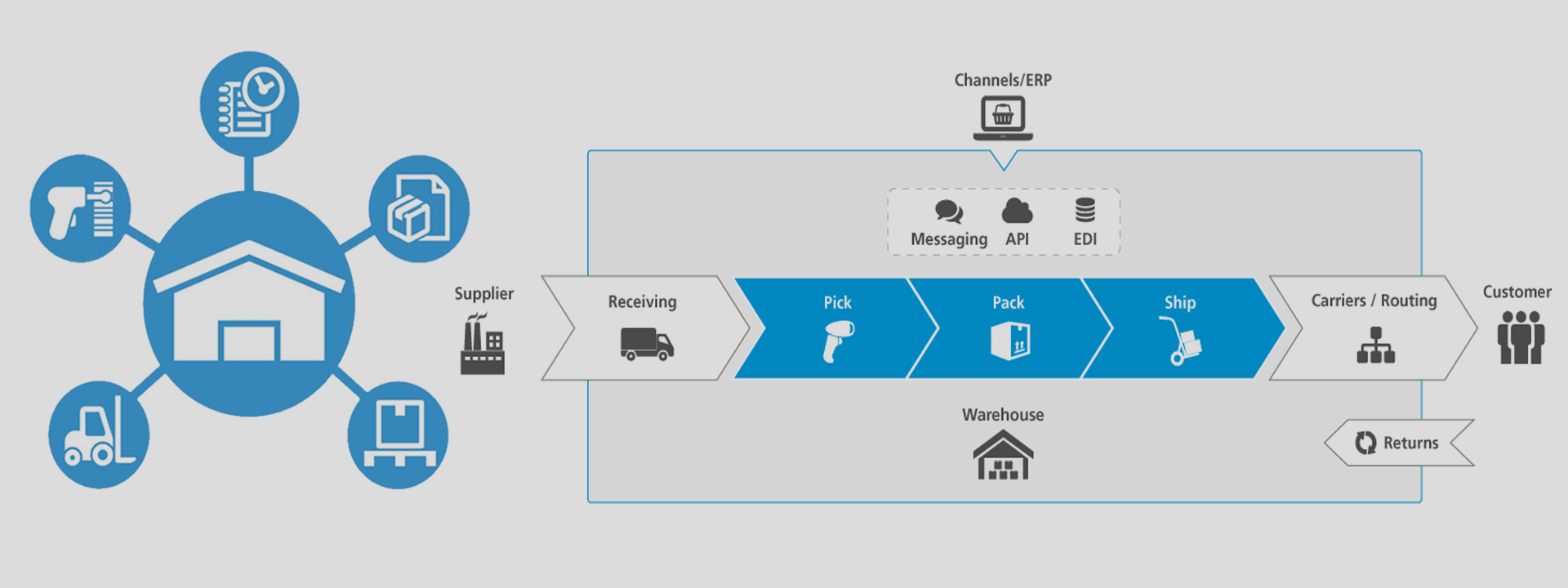

Being able to access critical operational data and processes from a mobile environment keeps operations running as smoothly as possible. Users can view the information gathered by the software solution from anywhere to make educated planning decisions.

Our WMS Inventory allows users to choose which modules they need to optimize workflows. Get what you need without extra functions that only clutter up your operation.

All of your important inventory and manufacturing management data is in one easy to access place, reducing unorganized documents and information.

This software solution contains functions that improve inventory organization and accuracy. By strengthening inventory processes, order life cycle time is reduced and customer satisfaction is increased.

This solution streamlines matching purchase orders to original orders. Fishbowl Inventory helps keep you on top of the constant flow of product in and out of a warehouse.

Plan out the layout of your warehouse according to the unique requirements of your operation. Products that typically move out faster than others can be placed in an optimized position with zoning tools.

Automation of tedious and complicated tasks helps keep human error from throwing a wrench into the works. Fewer mistakes mean fewer wasted resources, and more time spent working on pressing issues.

Key Features

Reordering can be automated along with streamline of pick, pack and shipping in order to optimize your supply chain. Inventory can be tracked with RFID, barcoding printing and scanning.

Get an overhead view of a multi-location operation with WMS tools. Monitor stock levels in multiple facilities, gain trend data across all operations and transfer products from one location to another to avoid shortages.

This feature allows you to know where the next part for your manufacturing operation is coming from. Set alerts for part replacement and track your ordered parts by location. Our Inventory also tracks parts and labour costs so you can keep track of preferred vendors.

This feature contains a Warehouse Control System module that provides integrations with material handling and voice solutions. Managers can monitor equipment in real-time while gaining visibility into the entire warehousing environment.

Our WMS supports multichannel fulfilment that allows customers to fulfil, buy and return products from a location that works for them. Larger enterprises can leverage the features of this system to streamline their fulfilment processes regardless of the complexity involved.

Our WMS features mobile access to provide users with a gateway into their operations at anytime from anywhere. Allowing users to be on the move while remaining up to date on important operational information frees up valuable resources.

Warehouses that implement cross-docking can cut down on material handling by reducing unnecessary put-away. These processes can be executed on an as needed basis or planned ahead of time.

Auditor-approved cycle counting features save warehousing operations both time and money. Instead of relying on physical counts, Our WMS allows clients to quickly run through cycle counts while freeing up employees for other, more important tasks.

This platform includes a number of tools for planning, measuring and reporting labour tasks while documenting the performance of team members. Our Software helps reduce unproductive time through indirect labour tracking.

Our WMS platform provides an advanced slotting algorithm that optimizes product movement through the warehouse. This feature can dynamically respond to a client’s unique warehousing environment and provide optimized slotting for products in the warehouse.

Multiple different automation systems ranging from pick-to-light, put-to-light and pick-to-belt are all supported. Collaboration with vendors and supplies is increased through integration with EDI, ERP and financial systems.

Third-party logistics providers can benefit from features crafted specifically for their unique needs. Giving your 3PL provides the tools they need to succeed allows them to fully optimize the warehousing operations they oversee.

Our WMS provides a number of advanced features for more complex warehousing operations. Leverage complex features like value-added services, lot management, serial number tracking and product recall functionalities.

WMS Benefits