The Industrial Internet of Things (IIoT) is the use of smart sensors and actuators to enhance manufacturing and industrial processes. Also known as the industrial internet or Industry 4.0, IIoT leverages the power of smart machines and real-time analytics to take advantage of the data that dumb machines have produced in industrial settings for years. Industrial IoT collects and analyses data to deliver insights that help industrial companies become nimbler, making better informed business decisions more quickly than ever before. Also, through the use of equipment and product data points, such as location data, industrial IoT is helping companies transform their manufacturing and industrial processes. This means better quality control, sustainable and green practices, and more efficient, streamlined supply chain management. It also benefits predictive maintenance, field service, energy and facilities management, and asset tracking. The driving philosophy behind IIoT is that smart machines are not only better than humans at capturing and analysing data in real time, they are better at communicating important information that can be used to drive business decisions faster and more accurately.

ALWAYS ON! ALWAYS CONNECTED!

Better Decisions in Complex Environments

Wireless Technology - A Comparison

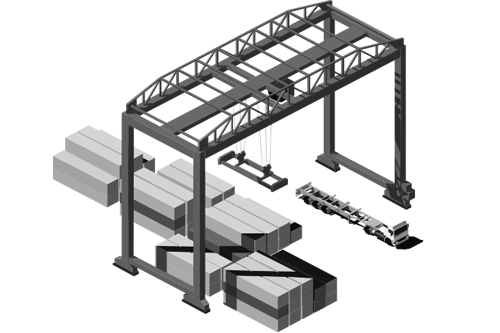

Smart Production Using RTLS

By making equipment intelligent enough to self-manage and collaborate with the rest of the manufacturing system, manufacturers can drive overall reliability, predictability and optimization.

Common Application of RTLS

One of the most basic functions of RTLS is to monitor and track the movement of your vehicles, equipment, and tools. With the right technology, you can actively observe vehicles traveling on a tarmac at the airport, find where tools have been left behind by workers in a large facility, and even make sure no equipment leaves a designated area.

Keeping track of personnel is also a vital function of a real-time location system. Businesses can use this technology to do virtual roll calls, monitor the active movements of staff members, check that staff are actually working, and even keep track of important data, such as hours worked, tardiness, and which employees used which equipment.

Tracking merchandise and inventory in a warehouse is another excellent way to utilize RTLS. With passive and active ID tags, facilities can automatically log the entry of merchandise from the loading dock and keep an accurate count of inventory. This information can also be used to track down point of origin when needed, monitor the production of raw materials, and easily distribute inventory to retailers and other facilities.

Sensors installed on ID tags that are affixed to vehicles and equipment can monitor the status of your ~/Content/assets and trigger alerts when maintenance is needed. You can also utilize RTLS to keep track of how often maintenance is needed on various equipment, monitor the results of maintenance and reduce repair costs from breakdowns.

Sensors can also be affixed to passive and active ID tags to monitor the environment, such as gas levels, temperature, humidity, and even vibration that could indicate an earthquake or rock slide. This is a great tool to use in hazardous environments like mining facilities and logging concerns.

ID tags worn by employees can also include Man Down alerts that trigger when the employee hasn’t moved for a long period or has even fallen. RTLS can also be used to assist with emergency evacuation, fire training, and collision avoidance. Real-time location software can actively monitor the movement of vehicles and equipment, such as forklifts, to prevent accidents and crashes.

Sensors can also be affixed to passive and active ID tags to monitor the environment, such as gas levels, temperature, humidity, and even vibration that could indicate an earthquake or rock slide. This is a great tool to use in hazardous environments like mining facilities and logging concerns.

Gateways set up within an RFID network can monitor passage of personnel to prevent unauthorized access to specific areas. Passive ID tags affixed to tools and equipment may even trigger an alert when someone walks away from the site with these ~/Content/assets. Panic buttons and alarms on ID tags also allow employees to request emergency assistance from security.

Practical Applications for RTLS and Key Benefits

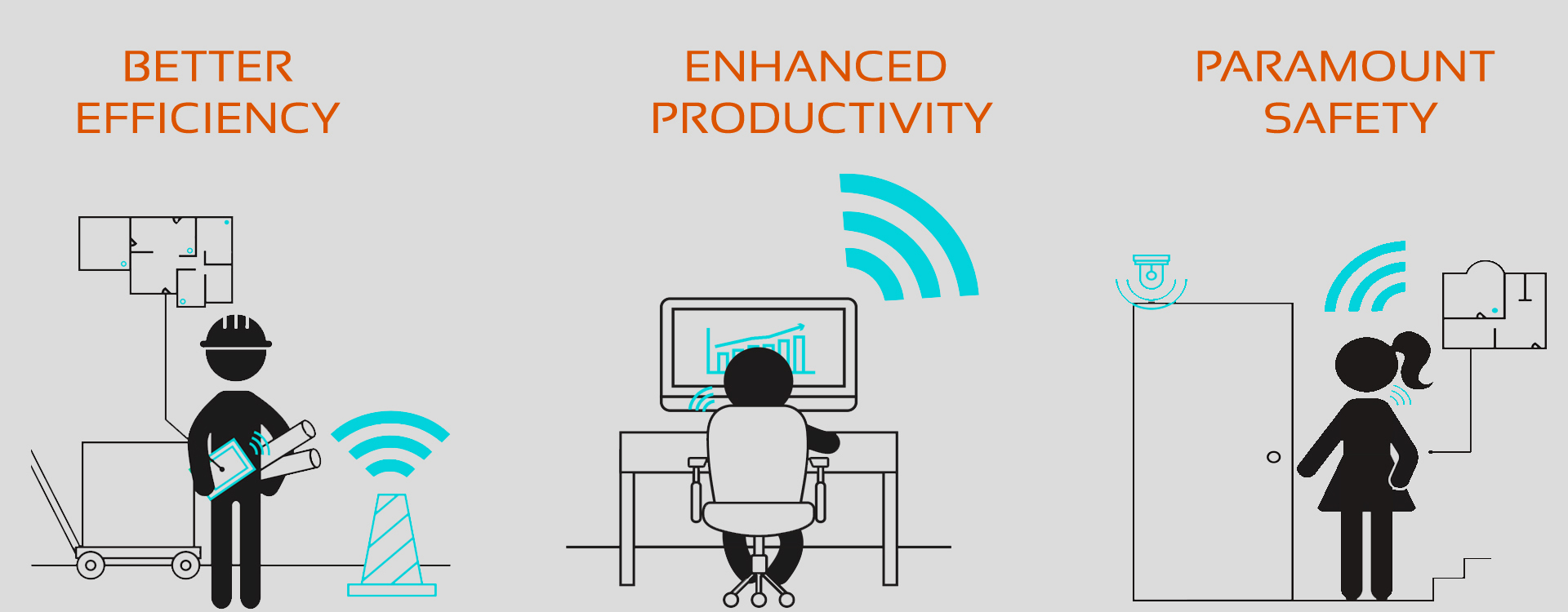

Applications of RTLS typically aim to improve operational processes and workflows; safety and security; inventory management, or a combination of all of these. RTLS solution implementation can help organizations address specific challenges they’re facing related to a range of causes including resource inefficiencies and even employee endangerment. Some of the practical application of RTLS are

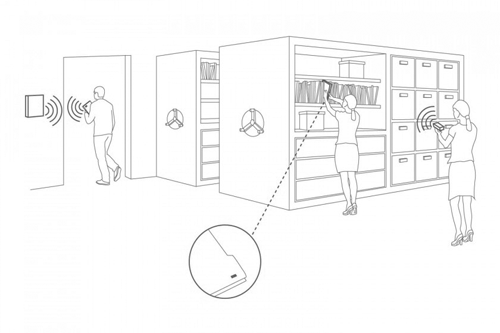

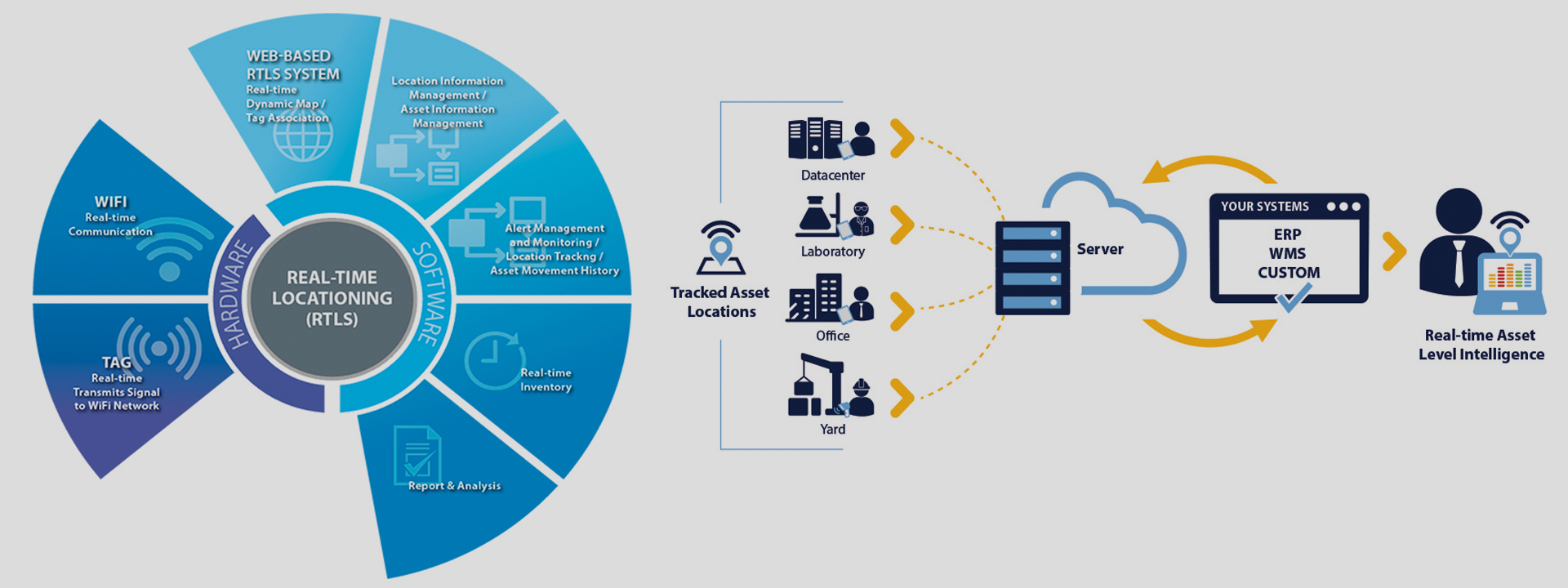

Working of RTLS

Tags establish the identity of the resource and broadcast that identity to readers

WiFi or Ethernet-enabled readers receive and transmit signals to the data processing engine in the Cloud.

The signals from multiple sensors are processed to estimate the position of the tagged resource

The various business rules around the positioning of resources are configured in the middleware.

Real-time data and historical records are presented intuitively on the dashboard.

Product and Services